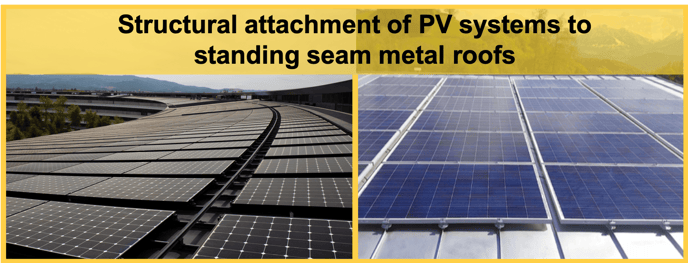

Can you save money by mounting solar on a standing seam metal roof?

Standing seam metal roofing (SSMR) is the most convenient of any roof type for mounting PV modules, either crystalline or thin-film.

Here are a few best design and installation practices for structurally attaching PV systems to standing seam metal roofs:

Standing seam metal roofing (SSMR) is the most convenient of any roof type for mounting PV modules, either crystalline or thin-film. The seams of SSMR are beam-like elements that not only add stiffness and flexural strength to the roof panels but also provide expedient attachment points for a PV system. Joining PV modules to this roof type can be done with or without continuous mounting rails using aluminum seam clamps.

Also, check out our project breakdown of a solar PV system using rails and using the direct-attach™ method: "5 Things to Consider When Wanting a Low-Cost Solar Module Mounting System".

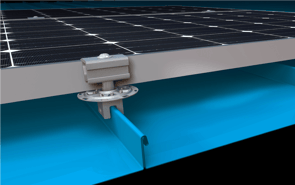

Seam Clamps and Mechanical Compression

These clamps anchor to the roof seam by pinching it within the clamp body with round-point set-screws that are in no way invasive to the roof. The setscrew forces the metal of the standing seam into a recess in the opposing clamp wall, permanently deforming it in order to establish a mechanical interlock. The clamp body is machined with threaded holes to facilitate the anchorage of PV modules or racking components to the clamp.

The SSMR industry has used this attachment technology for many years, and most SSMR manufacturers endorse and recommend this method when making attachments of various ancillaries to their roof systems. And it is a prime concern to all parties involved—building owner, roof manufacturer, PV integrator and code authority — that the integrity of the roof system is maintained and attendant warranties if any are in place, are not jeopardized.

The result is a PV-to-SSMR marriage that provides maintenance freedom for the expected service lives of both the PV system and the roof. When properly executed, these methods are not only dependable and expedient but also cost-effective.

12%-18% Savings Cost Using PV and Standing Seam Metal Roof

12%-18% Savings Cost Using PV and Standing Seam Metal Roof

Compatibility

Compatibility

Metallurgical compatibility is always important on a rooftop where materials will be in electrolytic contact. SSMR is most often steel, occasionally aluminum and very rarely copper, stainless or some other metal. Steel and aluminum may be pre-painted (coil coated) or bare (unpainted). The latter is something of a misnomer. This is because steel will always have a protective coating of pure zinc (galvanized) or an aluminum/ zinc alloy (Galvalume® or Zincalume®) for corrosion protection.

Aluminum seam clamps are compatible with all these metals except copper. When roofing is copper, brass seam clamps should be used. Somewhere between the brass clamp and the aluminum PV frame an electrolytic switch must be made. This can be done with a passive metal like stainless steel or with rubber isolators or both.

Click here to read the entire article for more best practices.