How far do you reposition ColorGard® from the eave and the second row?

Determining where to place snow retention rows is a common question. The first row is the easiest to answer, but it is really more of a question: "How much snow do you really want to fall off the roof?"

Determining where to place snow retention rows is a common question. We generally recommend that the first row be placed within 12 inches of the panel end. This recommendation is consistent with the Metal Construction Association “Metal Roof Design for Cold Climates” document has some commentary on pages 10 and 11 with respect to the first row of a snow retention system. This industry document recommends, “The first row of units or cross-members should be located close to within 12 in. of the eave end of the panels”.

The reason for this recommendation:

“This is because at some point, the snowbank that envelopes the snow guard will shear at the approximate location of the guard, and whatever portion of the bank is below the guard may fall from the roof.”

You will find several myths surrounding this topic, but the sighted “Metal Roof Design for Cold Climates” published by Metal Construction Association (MCA) is a good source of information to determine this and other cold climate designs. This document explains this question as well as many others regarding snow retention and metal roofing in cold climates.

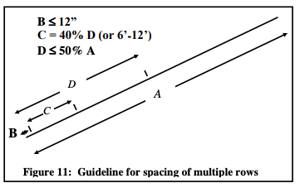

Figure 11 “Guideline for spacing of multiple rows” is a helpful resource found on page 10 of the MCA “Metal Roof Design for Cold Climates.” As you can see from the Figure 11 layout, snow retention products are preferred near the eave. This is because snow densifies and compresses most at this location.

Figure 11 “Guideline for spacing of multiple rows” is a helpful resource found on page 10 of the MCA “Metal Roof Design for Cold Climates.” As you can see from the Figure 11 layout, snow retention products are preferred near the eave. This is because snow densifies and compresses most at this location.

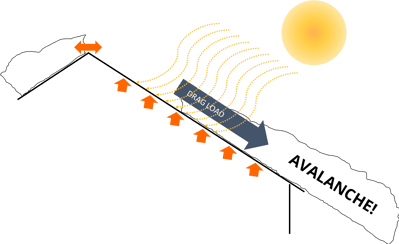

All snow guards rely on the compressive strength of the snowpack which is greatest immediately adjacent to the roof surface and especially at its eave end.

Another issue that is often overlooked, and can be very critical, is the potential need for a second row, even when calculations prove it is unnecessary structurally.

A thin blanket of snow can cause a “buckling blanket” effect especially when the blanket of snow on the roof is thin, dense and wet (not solidified). It may tend to undergo compression buckling, pushing a “loop” upward from the roof surface as the heavy mass compresses toward the eave where it is restrained by snow guards. This loop can fold over the snow retention device(s) in the downslope direction, often breaking and in some cases falling from the roof. A simple solution is to reduce the unsupported length of the snow blanket by adding a row or rows of snow guards.

For more information about MCA please visit their website: www.metalconstruction.org.