What clamp should be used on a copper standing seam?

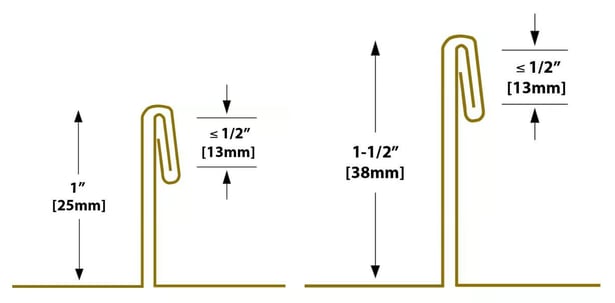

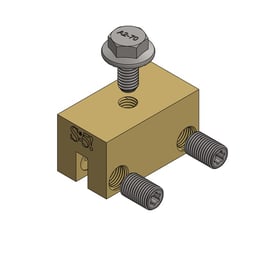

Traditional copper standing seam has been in use for about 1200 years. Our standard clamps are mill-finished aluminum, which in the presence of an electrolyte (like rainwater) can pose a risk of galvanic corrosion (to the aluminum) if used on copper roofs. This is why we recommend using our brass S-5-B (standard or Mini) clamps. The S-5-B is a brass clamp, metallurgically compatible with copper and is dimensioned for traditional double-folded copper standing seam. It has been load tested on both 16 and 20 oz copper double-folded seams.

Occasionally other standing seam profiles may be present in copper. If the copper roof in question does not fit within the slim throat of the S-5-B clamp, such as most snap-together profiles, another S-5! product option is the S-5-S clamp in stainless steel, which is compatible with copper. (Please note that this clamp may require manufacturing lead time.)

A final alternative for S, T-shaped or bulb-shaped seam profiles is to choose the aluminum clamps for these profiles, but anodize them prior to use. Anodization chemically induces formation of the oxide layer of the clamp components. Most respected metallurgists agree that this neutralizes the anodic behavior of the aluminum, reducing the potential for galvanic corrosion in all but highly acidic environments.