Why is ColorGard® a better choice than other color-coded options?

ColorGard is a better choice because of the perfect color matching—that lasts for the life of the roof.

It is no trick to achieve a perfect color match to the roof initially; numeric computer matching has made that task simple. The challenge is to keep it color-matched over time and exposure, because different pigments, paint resins and application technologies result with different aging characteristics. One paint fades much more rapidly than another, resulting in a very unsightly mismatch after several years.

It is no trick to achieve a perfect color match to the roof initially; numeric computer matching has made that task simple. The challenge is to keep it color-matched over time and exposure, because different pigments, paint resins and application technologies result with different aging characteristics. One paint fades much more rapidly than another, resulting in a very unsightly mismatch after several years.

The premium paint finishes used on metal panels are “coil-coated.” This paint application method utilizes state-of-the-art technologies, chemical pretreatment, primer and finish coat application, and controlled oven curing. Only through this lengthy process can high-quality Kynar and Hylar (PVDF) finishes be applied and warranted against color fade for 20 years and longer.

Our competitors have tried everything in their attempts to match the color and performance of factory coil-coating methods: Anodizing, powder coating, dye and air-dried paints—even powder coating with Kynar resin. But nothing ever comes close. Even when these methods produce perfect paint matches, the match doesn’t last. In a few short years the inferior paint on the snow guard reveals itself as it fades noticeably faster than the roof, creating an effect that is strikingly unattractive. Even powder coating with Kynar resin cannot equal the performance of coil-coated Kynar.

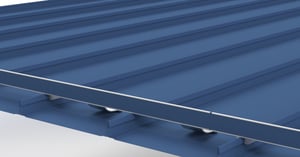

ColorGard is the only product that uses the same factory applied (coil-coated) finish and inorganic pigments as the roof itself. We do this by incorporating a strip of the actual roof material in the ColorGard system, for a perfect match of roof and snow guard for the life of the roof. You can also obtain an optional limited lifetime performance warranty* (at additional cost).